The XL (extra-large) range of dryers remove moisture from compressed air using the refrigeration principle.

Incoming air is cooled in two stages — firstly by dry air leaving the unit and finally down to dewpoint temperature using refrigerant.Shell and tube heat exchangers are used for both processes.

The dryers are supplied as compact free-standing units complete with fully automatic refrigeration control systems, electrical panels, drain valves etc.

| Model | Flow | Installed | Abs | Compr Cap | Water | Air Conns | Water Conns

(screwed BSP) |

||

|---|---|---|---|---|---|---|---|---|---|

| scfm | l/sec | kW | kW | kW | l/sec | Flanged | In | Out | |

| 260W100 | 3600 | 1700 | 7.5 | 7.5 | 33 | 1.9 | AS2129-E-150 | 1-1/4″ | 1″ |

| 350W150 | 4775 | 2250 | 11 | 10 | 39 | 2.2 | AS2129-E-150 | 1-1/4″ | 1″ |

| 420W200 | 5750 | 2715 | 15 | 12 | 47 | 2.3 | AS2129-E-200 | 1-1/4″ | 1-1/4″ |

| 520W250 | 7200 | 3100 | 18 | 15.5 | 60 | 3.4 | AS2129-E-200 | 2″ | 1-1/4″ |

| 615W300 | 8500 | 4012 | 22 | 17 | 70 | 3.2 | AS2129-E-200 | 2″ | 1-1/2″ |

| 800W350 | 11000 | 5192 | 26 | 23 | 91 | 5 | AS2129-E-200 | 2″ | 1-1/2″ |

| 860W400 | 12600 | 5950 | 30 | 25 | 105 | 5 | AS2129-E-300 | 2-1/2″ | 1-1/2″ |

| 1100W500 | 15000 | 7080 | 37 | 30 | 125 | 6.5 | AS2129-E-300 | 3″ | 2″ |

| 1310W600 | 18200 | 8590 | 45 | 36 | 158 | 8.5 | AS2129-E-300 | 3″ | 2″ |

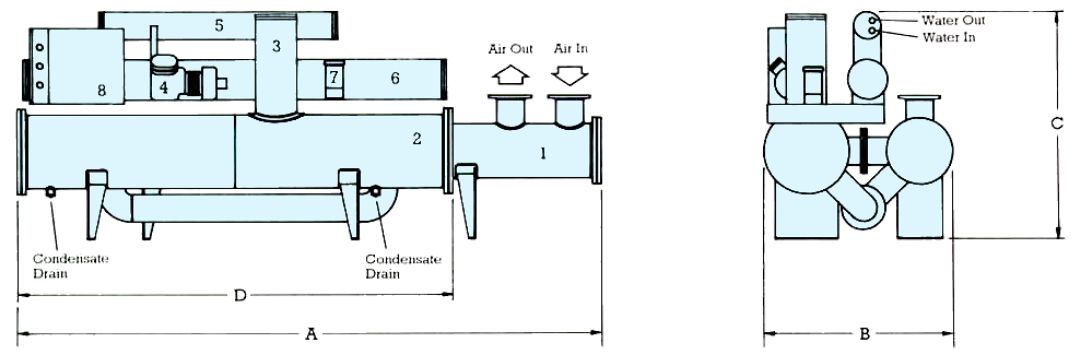

| Model | A mm | B mm | c mm | D mm | Weight kgs |

|---|---|---|---|---|---|

| 260WlOO | 3555 | 1348 | 1348 | 2966 | 2500 |

| 350W150 | 3569 | 1517 | 1517 | 2966 | 3067 |

| 420W200 | 4385 | 1528 | 1528 | 3193 | 3520 |

| 520W250 | 4396 | 1645 | 1645 | 3281 | 4118 |

| 615W300 | 4398 | 1750 | 1750 | 3130 | 4547 |

| 800W350 | 4412 | 1963 | 1963 | 3150 | 5500 |

| 860W400 | 5235 | 1993 | 1993 | 3180 | 6859 |

| 1100W500 | 5235 | 2200 | 2200 | 3643 | 7300 |

| 1310W600 | 5279 | 2354 | 2354 | 3663 | 7800 |

Air dryers are essential for the mining industry, where the presence of water can cause corrosion, damage, and inefficiency in the equipment and processes. Air dryers can also improve the quality and safety of the products and materials that are mined or processed.

Air dryers play a crucial role in aluminium smelting. The purpose of air dryers is to remove moisture and other volatile components from the aluminium, ensuring it is ready for further processing. By effectively drying the aluminium, air dryers help maintain the quality and integrity of the metal during subsequent stages of smelting and refining.

These industries use dryers for processing metals and minerals. The dryers are used for drying ores, extraction products, metal sheets, metal powders, metal castings, slags, or scrap metal. The dryers can also dry binders that form and hold together agglomerates.